Presswood Pallet Production Line

Pressed wood pallet production line is mainly designed for producing presswood pallet by compression molding with raw materials of wood sawdust, wood shaving, wood chips, straw, coconut fiber (coir) and other fibers.

Raw materials: waste wood, sawdust, wood chips, wood shavings, raw wood, burned wood, logs, wood board, tree branches, timber, wood planks, waste pallets and so on. Other materials containing rich fiber also can be used for production of pressed wood pallet, such as straw (wheat/corn), waste paper, bamboo, palm trees, coconut fiber (coir), softwood, bagasse, miscanthus and so on.

The final product: Pressed Wood Pallet; Presswood Core Plug; Presswood Cable Reel; Wood Fibre Board etc.

Main Machines of Production Line

Wood Chipper, Wood Crusher, Drying Machine, Glue Mixer, Presswood Pallet Machine, Mold Temperature Controller

Process of Presswood Pallet Production

Advantages of Pressed Wood Pallet Production Line

- High efficiency

The production line with one compression molding machine can produce 180 pieces of pressed wood pallet each hour by adopting automatic material spreading, automatic hot pressing, automatic push-out and automatic stacking. - Full automatic

Full automatic production solution can be provided for this production line. Only one or two working staff is enough to deal with the regular operations within the whole production line. - Cost saving

This production line can significantly decrease the cost of raw materials by using waste wood, wood sawdust, wood shaving, wood chips, straw, coconut fiber (coir) and other fibers. - Wide range of application

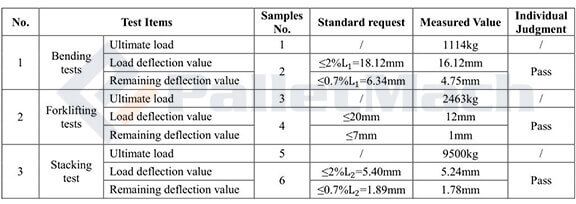

By simply changing the compression molding, pallets in varied shapes/sizes could be produced. - High quality of final product pallet

The pressed wood pallet is of high quality with smooth surface, high loading capacity, good performance in water proof resistance and non-fumigation. - Environmentally friendly and energy saving

The heat source of this production line can be supplied in multiple ways. The energy consumption is low. It is an ideal option to recycle wood waste in an environmentally friendly way.

Customer Site Display