Wood pallet chamfer machine is mainly used for wooden pallet production. The chamfered wooden pallet is easier for forklift operation, preventing damage to the pallet due to forklift operation errors.

Chamfer function: easy and quick fit into for forklift, fork truck or pallet jack.

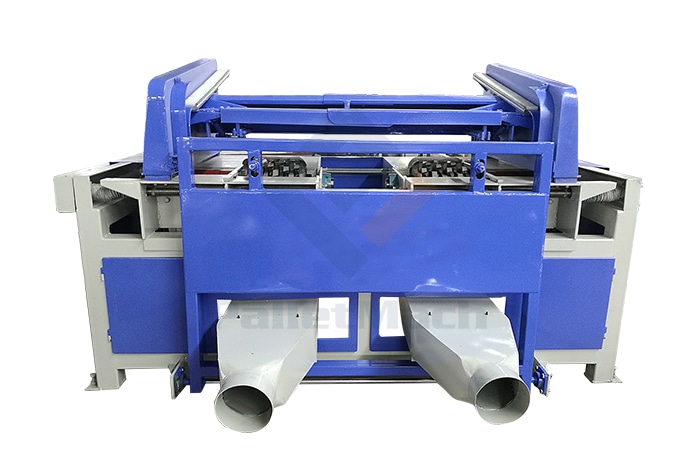

When the equipment is running, the worker puts the whole piece of wood to be processed on the operation table. When placing the wood, it is necessary to pay attention to placing the wood in the feeding trough of the machine operation table to prevent the wood material from shifting during the movement. The wood is pushed forward at a constant speed to the cutting blade as the chain runs, and the blade rotates the milling edge. The wood from the side of the milling is pushed along with the running chain to the finished product discharge chute, and the milling process is completed.

Product advantages

- The size of chamfer can be adjusted, the cutting size is accurate, the surface of the cut material is smooth and burr-free.

- PLC control, automatic feeding, high production efficiency, 1 person can operate.

- The cutter is made of alloy material, sturdy and durable, easy to replace.

- Equipped with dust removal and dust collection device to reduce dust pollution.

- Simple operation, increase protection and emergency stop device, protect personnel safety.

Pallet chamfer machine parameter

| Modelo | PM-400DB |

| Processing size | Length: 600-1500mm, Width: 80-150mm, Height: 17-35mm |

| Capacity | 400pcs/h |

| Power | 4kW |

| Dimensions | 3400 x 850 x 1500 mm |

| Weight | 800kg |