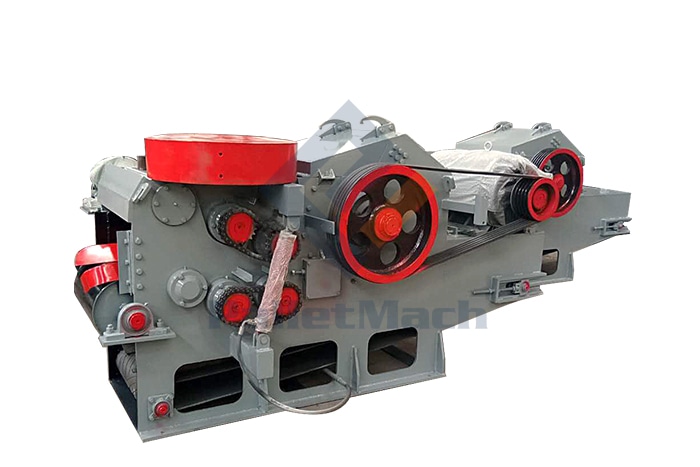

Drum wood chipper machine belongs to wood processing equipment series. Drum wood chipping machine is widely used in wood working factories, furniture factories, wood pallet plants, pallet block production lines and other wood industrial production factories.

Drum wood chipper is the best equipment for preparing material for molded wood pallet and pallet block production.

Drum wood chipping machine has the advantages of wide application, diversified raw materials, good quality wood chips, safe and reliable, and high production efficiency.

Wood materials enter the chipper cavity through the conveyor system and the feeding port. Wood materials are chipped into wood chips under the shearing stress of the high-speed rotating flying knives and the bed knife installed on the machine base. The qualified chips pass through the screen holes below the knife roll and are discharged through the discharging port. A little larger wood chips, which cannot pass through the screen holes, continue to be chipped again.

Drum Wood Chipper Machine Model Parameter

| Drum Wood Chipper Parameters | ||||

| Model | PM215 | PM216 | PM218 | PM2113 |

| Knife-cylinder diameter(mm) | 500 | 600 | 800 | 1300 |

| Feeding port size (mm) | 160*400 | 230*500 | 320*680 | 380*700 |

| Fly-cutter qty (piece) | 2 | 2 | 2 | 2 |

| Revolving speed(rotate/minute) | 590 | 590 | 650 | 500 |

| Feeding raw materials max diameter(mm) | 160 | 230 | 300 | 350 |

| Chip size(mm) | 15-30 | 15-30 | 15-30 | 15-40 |

| Production capacity(ton) | 3-5 | 6-9 | 9-15 | 12-25 |

| Main motor power(kW) | 45 | 55 | 110 | 200 |

| Feeder power(kW) | 2.2-3 | 3-4 | 4-5 | 4-5 |

| Conveyor power(kW) | 3 | 3 | 3 | 3 |

| Dimension(m) | 1.47*1.55*0.97 | 2.95*1.9*1.5 | 2.2*2.15*1.5 | 3.67*2.517*2.05 |